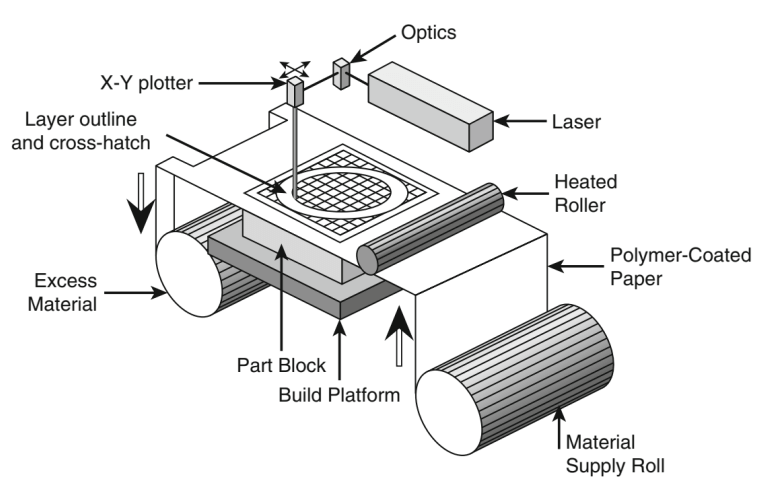

Lamination is the technique process of manufacturing a material in multiple layers so that the composite material achieves improved strength stability sound insulation appearance or other properties from the use of the differing materials such as plastic a laminate is a permanently assembled object created using heat pressure welding or gluing.

What does lamination of steel mean.

Small hysteresis area resulting in low power loss per cycle low core loss and high permeability.

Processing can create layers in materials such as steel formed by rolling and plastics and metals from 3d printing which can fail from layer separation.

Electrical steel is usually manufactured in cold rolled strips less than 2 mm thick.

Electrical steel lamination steel silicon electrical steel silicon steel relay steel transformer steel is an iron alloy tailored to produce specific magnetic properties.

Lamination defect in steel plates is highly undesirable for dynamically loaded elements of steel structure such as high pressure temperature storage tanks vessels.

Thus delamination is an insidious kind of failure as it develops inside of the material without being visible on the surface much like metal fatigue.

Delamination is a mode of failure where a material fractures into layers.

A variety of materials including laminate composites and concrete can fail by delamination.

The state of being laminated.

The cause of delamination is weak bonding.

Delamination when a laminated material becomes separated perhaps induced by poor processing during production impact in service or some other means.